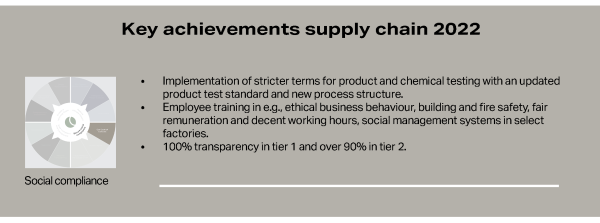

We respect the fundamental human rights throughout our supply chain and strive for continuous improvements of working conditions. In the coming years, our focus lies on increasing supply chain transparency, improving average audit score, and securing fair wages for more people. To reach our goals, our partners must be devoted to improve working conditions both in their own facilities and together with their supply chain partners.

Our code of conduct

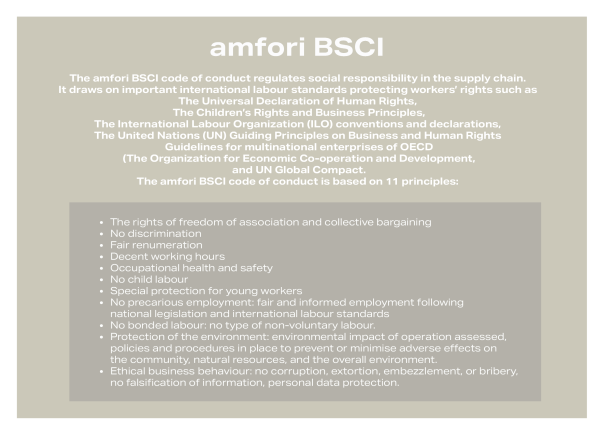

Björn Borg has been a member of amfori for many years and applies the amfori BSCI code of conduct. All our suppliers must sign and commit to comply with the code of conduct and compliance is verified through recurring audits. We work either with agents or directly with the factory owners in the countries where we produce our garments and are in close-to daily contact with them. amfori has updated the code during 2022 for implementation during 2023.

All Björn Borg footwear production facilities are fully audited, either through amfori BSCI or SMETA. Many of them also apply The Higg Facility Environmental Module (Higg FEM), a sustainability assessment tool that standardizes how facilities measure and evaluate their environmental performance, year over year. Staff from our footwear licensee’s offices in China and Portugal visits factories regularly. Our licensee for eyewear works actively with its suppliers and normally performs regular factory controls.

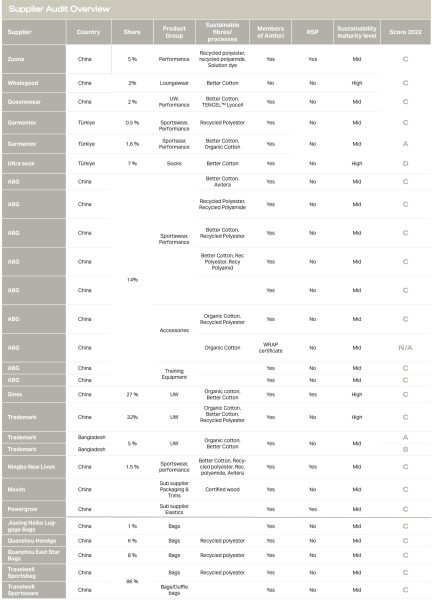

Audits

Audits booked through the BSCI system are made by an independent inspection firm checking thirteen different Performance Areas during the audit. They interview workers, check documents, and thoroughly go through everything that has to do with social compliance. This system gives us a complete overview of the audit results of all the factories where we produce.